Portfolio

Custom design prefab house in a seaside village

Area: 100 m2

Floors: 1

Floors: 1

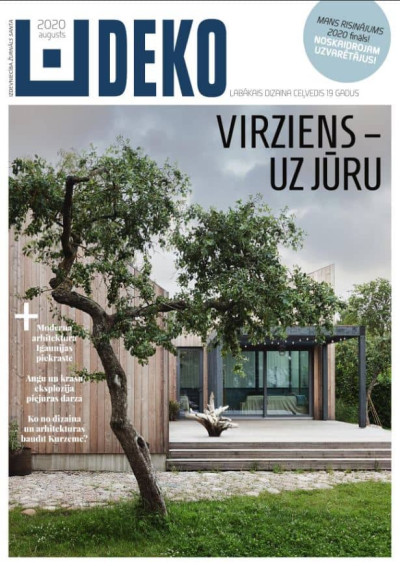

ZTC finished works on a one storey 100 m2 vacation house project in a seaside village in Latvia. This project was an example how the high quality and reliability of house prefabrication can be applied with highly individual design solutions.

The building was designed with a historical looking street-facing facade with naturally aged wood shingles and larch siding boards. Custom produced wood laths were used to makethe high quality triple pane windows fit with the historical design. However the building has a very modern look from the yard with large windows, an open pergola and glass roof. The house features a rainwater collection system that is integrated in the facade and a wall width glass doors to the terrace to get clean architectural shapes.

The building air tightness performance was tested with a blower door test and the results were significantly better than required by Passive House standard. Leakage through gaps was 0.39 of the total house volume per hour during a pressure test at 50 Pascal where Passive House standard requires 0.6. The pergola was painted with special wood tar paint. The roof was insulated with cellulose insulation that has higher thermal inertia than conventional mineral wool insulation. That provides an even temperature throughout night and day.

Scope of ZTC work

ZTC prepared production drawings for wooden constructions of the prefab wood house, produced the construction elements (panels with windows and doors already fitted in the factory and other elements) and organized transportation of the building kit. A team of ZTC workers assembled the building on site, installed the larger windows, did air sealing and exterior finishing works such as siding with vertical wood boards.

Laying of foundation, construction of ground floor, interior engineering communications (piping, wiring) and interior finishing was organized by the client.

The building was designed with a historical looking street-facing facade with naturally aged wood shingles and larch siding boards. Custom produced wood laths were used to makethe high quality triple pane windows fit with the historical design. However the building has a very modern look from the yard with large windows, an open pergola and glass roof. The house features a rainwater collection system that is integrated in the facade and a wall width glass doors to the terrace to get clean architectural shapes.

The building air tightness performance was tested with a blower door test and the results were significantly better than required by Passive House standard. Leakage through gaps was 0.39 of the total house volume per hour during a pressure test at 50 Pascal where Passive House standard requires 0.6. The pergola was painted with special wood tar paint. The roof was insulated with cellulose insulation that has higher thermal inertia than conventional mineral wool insulation. That provides an even temperature throughout night and day.

Scope of ZTC work

ZTC prepared production drawings for wooden constructions of the prefab wood house, produced the construction elements (panels with windows and doors already fitted in the factory and other elements) and organized transportation of the building kit. A team of ZTC workers assembled the building on site, installed the larger windows, did air sealing and exterior finishing works such as siding with vertical wood boards.

Laying of foundation, construction of ground floor, interior engineering communications (piping, wiring) and interior finishing was organized by the client.