News

Blower door test reveals quality of work in Ljustero project

02.11.2020 21:44

Blower door test reveals quality of work in Ljustero project

ZTC is about to complete the third stage of a development project in Ljustero, Sweden. A blower door test was carried out in the residential buildings in the project which all showed results that meet the requirement of the Passive House standard.

A blower door test was carried out in three various buildings all performing well in the air-tightness test. Although the houses are not planned to meet the Passive House standard, the N50 results of the three houses were 0.41, 0.52, 0.55 which are all within the air-tightness standard for Passive House standard of N50<0.6. The test was carried out by an independent construction consulting company.

Air tightness greatly impacts energy efficiency

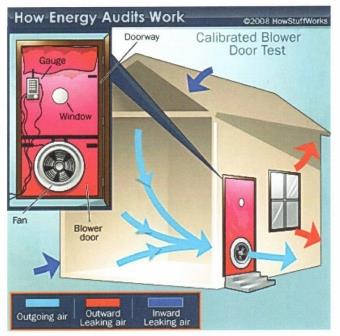

Air tightness is one of the main factors of energy efficiency of a building – preventing loss of energy due to air leakage. A blower door test is also used to find defects in the building envelope. Air tightness of the building envelope depends on the quality of used materials, the solutions of the manufacturer for panel connection seams, window and door installation, execution of this in the factory and the quality of work of the installation team.

Blower door test procedure

Blower door test is a globally recognized and widely used building air tightness testing methodology. The result is a measure of how much of the air volume escapes the building per time unit at a pressure difference between outside and inside of 50 Pascals.