Making sense of prefab construction – panelized or modular

You have probably heard the terms “prefabricated”, “modular”, “panelized” or “kit homes” when it comes to home building. Although they’re sometimes used interchangeably, there are significant differences between these types of construction. There are also various technologies of panelized construction so we give you a brief overview of their differences.

Wooden house construction

When it comes to building houses with the load bearing structure made of wood these can generally be divided in the following:

- On-site construction. Traditional “stick-building”, where all the parts are measured and cut on-site does not use prefabrication and is slowly but surely losing its place in buildings larger than a single family home.

- Prefabricated construction. Prefabricated homes (or prefab) is a broad term that refers to several types of construction. In principle it refers to a method of construction where a structural and building envelope elements are prepared in a factory according to a specific building design and then assembled on site. The main methods of prefabrication are panelized and modular construction.

Here is a comparison of the pros and cons of construction methods.

| Constraints | On-site Stick-built | Prefabricated Panel element | Module/volume element |

| Work time on site | Most | Middle | Least |

| Necessary on site labour skill level | Most | Middle | Least |

| Waste | Most | Middle | Least |

| Dependence on weather conditions | Most | Middle | Least |

| Engineering complexity | Least | Middle | Most |

| Project planning complexity | Least | Middle | Most |

| Design constraints | Least | Middle | Most |

| Benefits | |||

| Efficiency of material delivery to site | Middle | Most | Least |

| Flexibility for changes to design, details during execution | Most | Middle | Least |

| Construction process predictability | Least | Middle | Most |

| Dependable quality standards | Least | Middle | Most |

Panelized vs Modular

Wooden panelized (panel element) and modular (volume element) construction address two problems presented by conventional “stick-built” construction: it is difficult to build accurately when you must cut and assemble every piece of the house on-site, and building that way takes a great deal of time. Prefabrication is more accurate and it is faster.

Modular houses

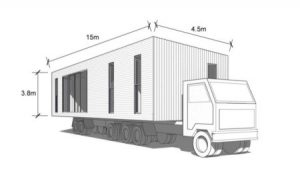

In modular or volume element construction, whole portions of the house are built as fully-finished volumes, which are then trucked to the building site and lifted onto a pre-built foundation. The main advantage of module construction is maximum level of prefabrication with interior works already mostly completed in the factory. That ensures factory production quality and reduces on site labour to a minimum.

One drawback is that every detail has to be clear at the outset and are costly to change once production has started. The fact that modules must be trucked down highways sets specific limitations on the maximum width of modules which reduces the flexibility of their design. Furthermore, a module takes much more space than the individual elements in it so transport costs are significantly higher than with other systems. The sheer size of house-modules prevents them from being shipped down narrow or steep roads that lead to remote sites. Also the availability of a suitable capacity crane in remote locations such as islands can make this solution infeasible. And modules are subject to damage if they are shipped over long distances — from wind and rain and roadway vibration.

Panelized houses

In panelized construction, only the exterior shell of the house is pre-built/produced in the factory (interior finishes are added later, in some cases external cladding can also be done in the factory), and that shell is broken down into a series of flat panels and other elements dimensioned so that they can be shipped on a standard truck, then installed on a built foundation. Depending on manufacturers offer or clients requirements the panels may be nothing more than a precisely produced frame with sheathing or finished with insulation, interior sheathing (e.g. drywall), installed electric conduits, windows and doors.

This method mostly provides the optimal level of prefabrication for flexibility during project execution and transportation costs.

There are several technologies in the panelized building system, so below we review some of them.

Wooden frame panels

Wooden panels are the most common, time tested and familiar panelized building system. It is an evolution of conventional stick frame houses to get higher quality in prefabrication. The commonality of this system is one of its main advantages – experienced producers who are able to produce a quality product and skilled specialists for on-site installation are available. Also remodelling of such a house in the future is pretty straight forward for most contractors.

However there still are significant differences in the solutions, materials used in the panels and the quality of production so choosing the right company is key.

Because stick frame building is very common, there are many start-up wooden panel production companies trying out their luck that come and go, so caution regarding quality standards and accountability in the long term is appropriate.

Structural insulated panels

A more recent technology is to build with structural insulated panels or SIP construction. SIPs are made of 3 layers – OSB/3 sheets on the inside and outside and foam insulation core, usually expanded polystyrene (EPS). The main advantage of this technology is its great thermal insulation properties due to the minimum amount of thermal bridging.

The main drawback of this technology are the risks associated with possible air or water leakage in the envelope that may arise in case of bad quality of connections between panels or damage. EPS essentially does not soak up and give out humidity, therefore if the structural OSB layers become wet, the consequences potentially are serious structural problems. Also with this technology not being widespread, it could prove difficult to find a contractor who can do remodelling works afterwards correctly (e.g. installing a new window). Also SIP construction is in general 20% more expensive than equivalent wooden panels.

Cross laminated timber panels

Cross laminated timber panels (XLAM, KLH or CLT for short) are a material that has been developed to be an equivalent of reinforced concrete panels in their load bearing capacity but lighter in weight. Therefore CLT panels can be used where larger spans are necessary so their application is usually in public and commercial buildings. CLT is also commonly used where the architect or client wants to use the aesthetic and sustainability properties of mass timber.

Infill panels

Apartment, public and commercial buildings are often built using infill panels which are installed on a steel, concrete or timber structure. This way the panels have to take just the load of their own weight, facade and the wind loads that affect them. Instead of building masonry, light steel or stick frame walls on the structure on-site, using factory produced infill panels considerably shortens on-site works. Most apartment buildings over three storeys in Scandinavia are built with wooden infill panels. Besides wood frame panels other infill panel solutions are widely used such as pre-cast concrete panels, lightweight steel frame panels, sandwich panels – each with its most suitable use.