Useful information

Prefab house price offer comparison – avoid common mistakes!

03.08.2020 20:05

How to compare timber frame prefab house price offers?

One very common topic that comes up with potential clients is comparing prefab house price quotes of alternative suppliers with our offering. The most significant price differences are due to what materials and works are or aren’t included. Often alternative quotes do not state this clearly enough for the customer to notice the difference. This article is intended to help you spot the most common examples.

There are four guiding principles:

- If the quote does not actually say something is included – don’t assume that it is. Quotes often contain a long list of “omissions”, so please read these carefully.

- Don’t assume that the price highlighted first is the all-inclusive sum. Often there are additional costs further in the detailed description.

- Go through the quote and highlight all areas where quantities or costs are “estimated”, “provisional” or “prime cost sum”. Theses are the costs that most likely will increase after you decide to go further with the supplier.

- If in doubt – ask.

House assembling

This is an area with many opportunities for misunderstanding. Here are some questions to consider:

Who is taking the responsibility for checking the assembling team work?

- Don’t assume that the panel producer will have a project manager who you can liaise with about deliveries or quality. Often the assembling team is left on their own.

- Who pays for the erectors travel, accomodation and insurance is often in the non-included list at the end of the price offer. A typical solution is for the supplier to cover the travel and insurance costs and leave the accommodation question to the customer because often the customer is best suited to find an optimal solution.

- A price for house assembling is listed in the quote does not mean that the house manufacturer is the one employing them. There are quotes that turn out to be “supply only” where assembling quote is appended for the client to employ them directly. Before choosing this way one should be confident about their knowledge and experience in construction and feel sure that the assemblers will be accountable in case of bad quality work.

- Don’t assume that the assembler will unload your delivery. Panel unloading requires a suitable crane, so find out who will procure the services. Often assembling is done directly from the delivery truck because there is no place to store large elements on a confined building site. This requires more meticulous planning, extra time from delivery trucks but saves on the more expensive crane time and decreases amount of handling of the elements.

Steelwork

A very typical “omission” is steelwork or stating in the quote that “additional” steel above that estimated will be chargeable.

Transport

A potential problem can arise with the vehicle size for deliveries. What size truck can get to your construction site? Usually transport costs are calculated for a standard semitrailer truck (with 13,6 m long load length). The price offer can hava a limitation clause that, if non-standard vehicles are required, this is chargeable.

What is it you’re buying?

External walls

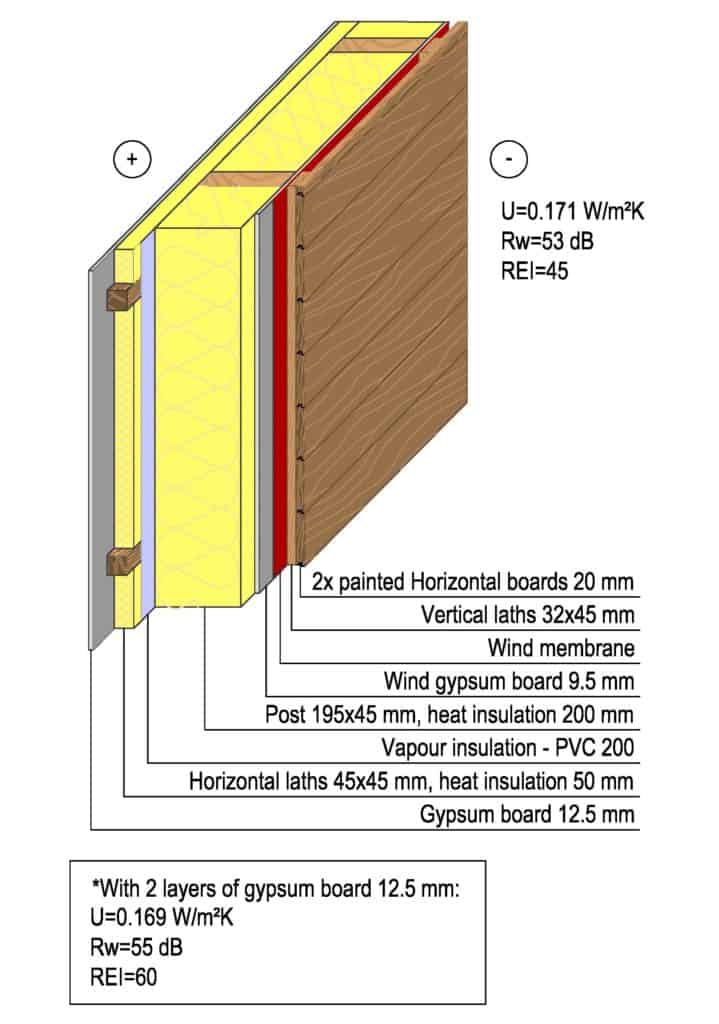

Although producer’s brochure might show a finished wall it doesn’t mean that’s the scope of supply. Often the price offer includes walls without external finishing. What is included and who fits it? The panel will not have the vapour control layer if there isn’t a service zone behind the plasterboard. In this case the vapour control layer often isn’t included or left to be installed by the client. Is the insulation added in the factory, to ensure highest quality?

It is best practice to describe all element layers in the prefab house price offer or attach a detailed drawing.

Internal walls

As a minimum all building kits will include the load bearing structural walls but what about non-structural walls? These can be omitted all together, sent as panels or assembled together with the structural walls.

Scope of supply

Often offers that seem expensive are just offering more than just the minimum. We recommend you make a list to compare these to each other. If you are building a custom design house, then you can get the best comparison of quotes by specifying the necessary characteristics and works in your request for quotation. That requires a bit more thorough knowledge of construction and available solutions where a consultation with a specialist is useful.

What a quote won’t tell you?

Building a house is a big investment, so it’s important to know who you give your money to. Usually part of the prefab house price is paid in advance before each stage of making manufacturing drawings, manufacturing itself and delivery, therefore you must be sure who you entrust your money with before you see a tangible result on the construction site.

However you won’t find evidence of the most significant aspects that determine the quality of the house – energy efficiency and long term performance, in the quote.

Here the most important questions are:

Does the producer have a good reputation? Does the company give a good impression of its technical knowledge? How long has the company been in the market and how sure you are the company will exist in the future? Does the company buy materials from quality suppliers? What are the payment conditions?

There are plenty of opportunities to save costs on materials. The prefab house price depends on what quality timber is used, what corrosion class metal is used for finishing details, which producer’s tapes are used for connections, membrane for wind barrier etc. The materials used directly impact the longevity of the house, amount of maintenance and energy efficiency performance.

There are suppliers who give you the best offer first and through conversation with the client reach the optimal solution for the client’s possibilities. There are, on the other hand, those starting with a bare bones offer with the lowest prefab house price. Therefore the ability of the supplier’s representative to find the best solution together with you is paramount.

A house is built for a long life so you must be confident that you will get a quality home and will be able to address your questions to the supplier in the future.